Support Structures

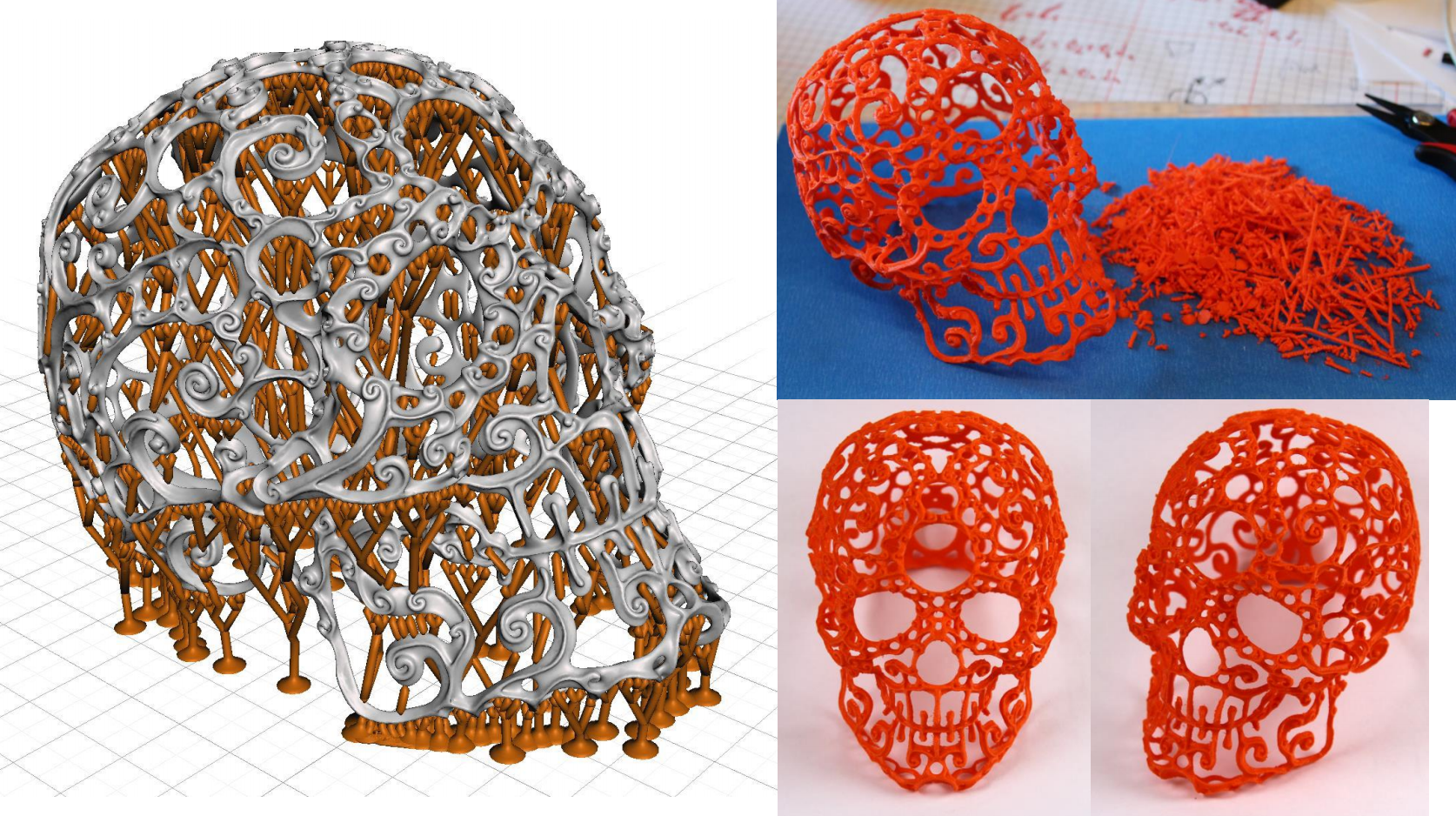

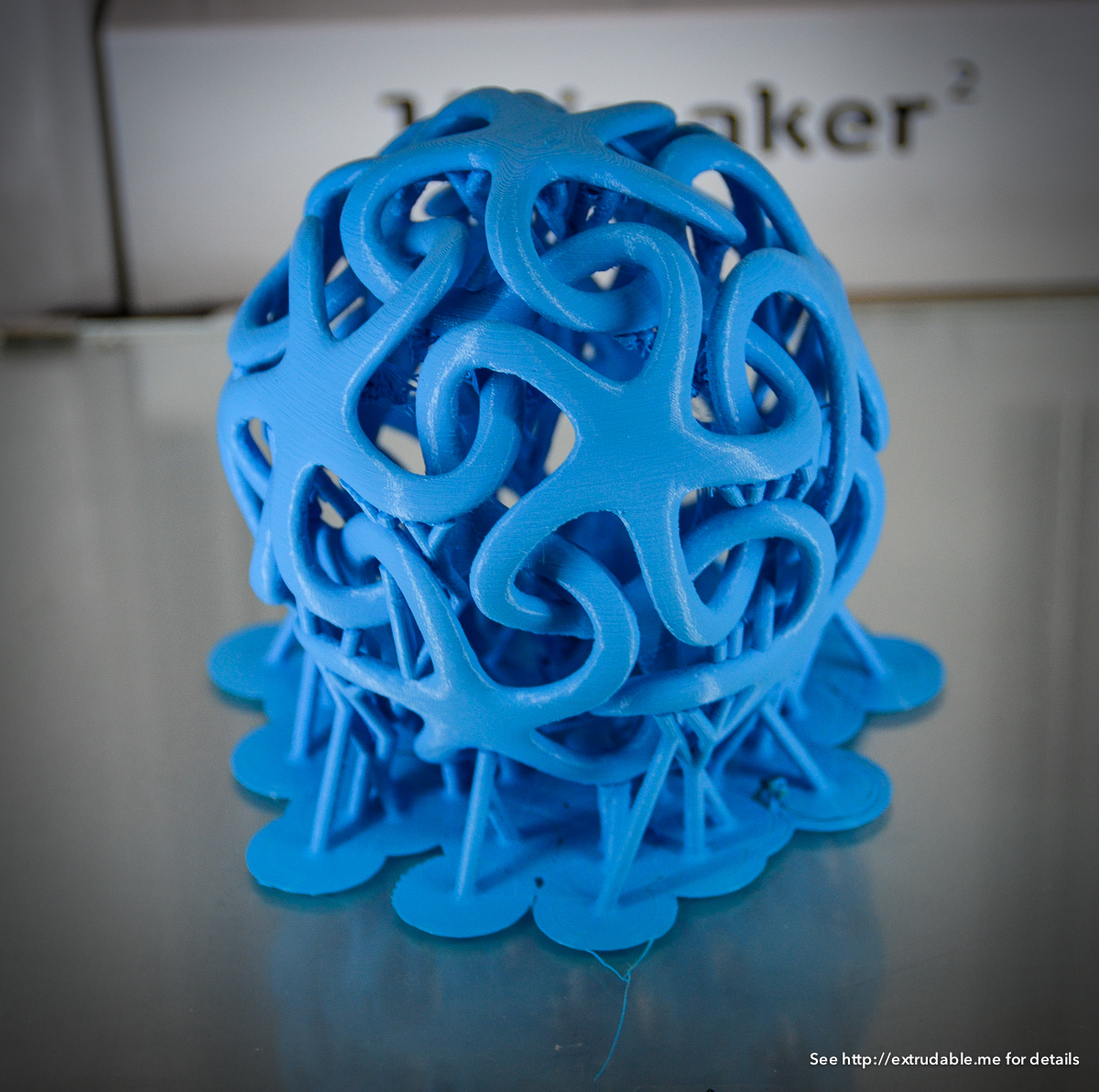

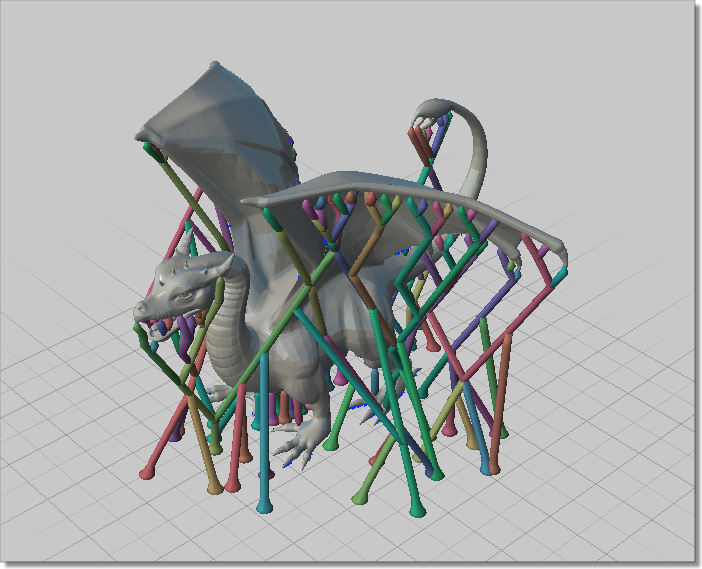

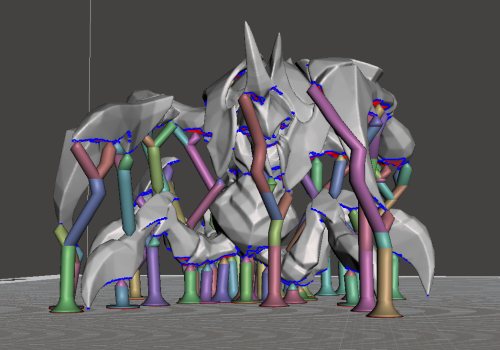

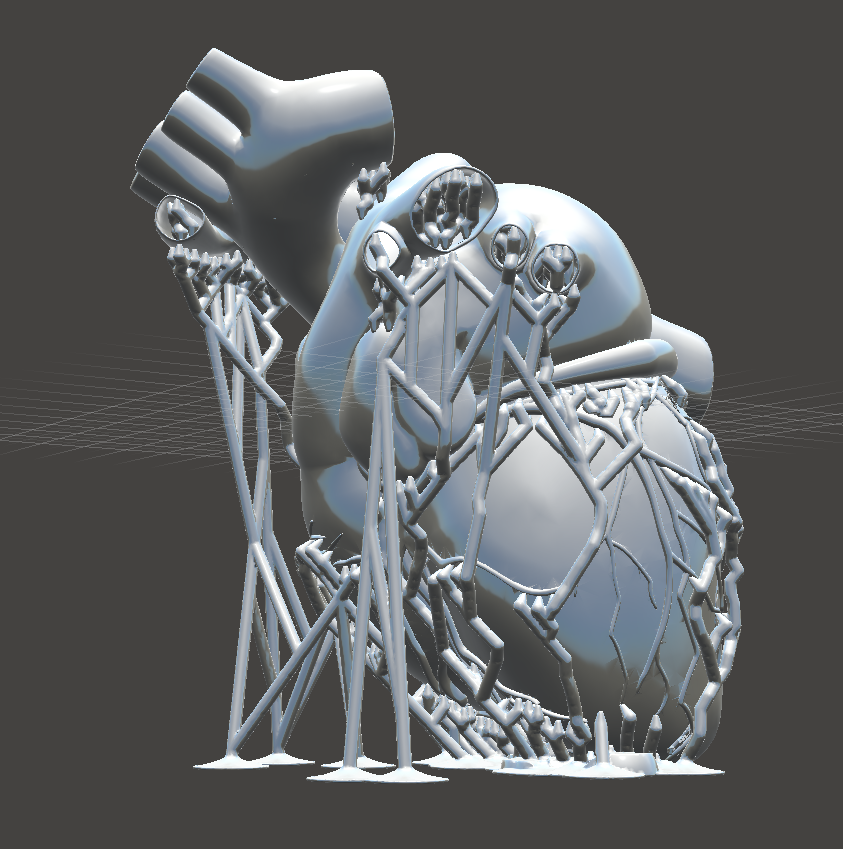

Perhaps my most significant contribution to the state-of-the-art in 3D printing is my hierarchical branching support structures technique. I developed this technique over the summer of 2013 at Autodesk Research, and we released it as part of the major Meshmixer 2.0 update in September 2013. At the time, the only other option (provided by most print software) was to fill the areas under overhangs with "solid" blocks of sparse printed material. This wastes quite a bit of print material, vastly increases print time, and is incredibly difficult to remove. In some cases you would always break the print trying to get the support off. Click the right-arrow on the image to the right to see what this kind of support structure looks like.

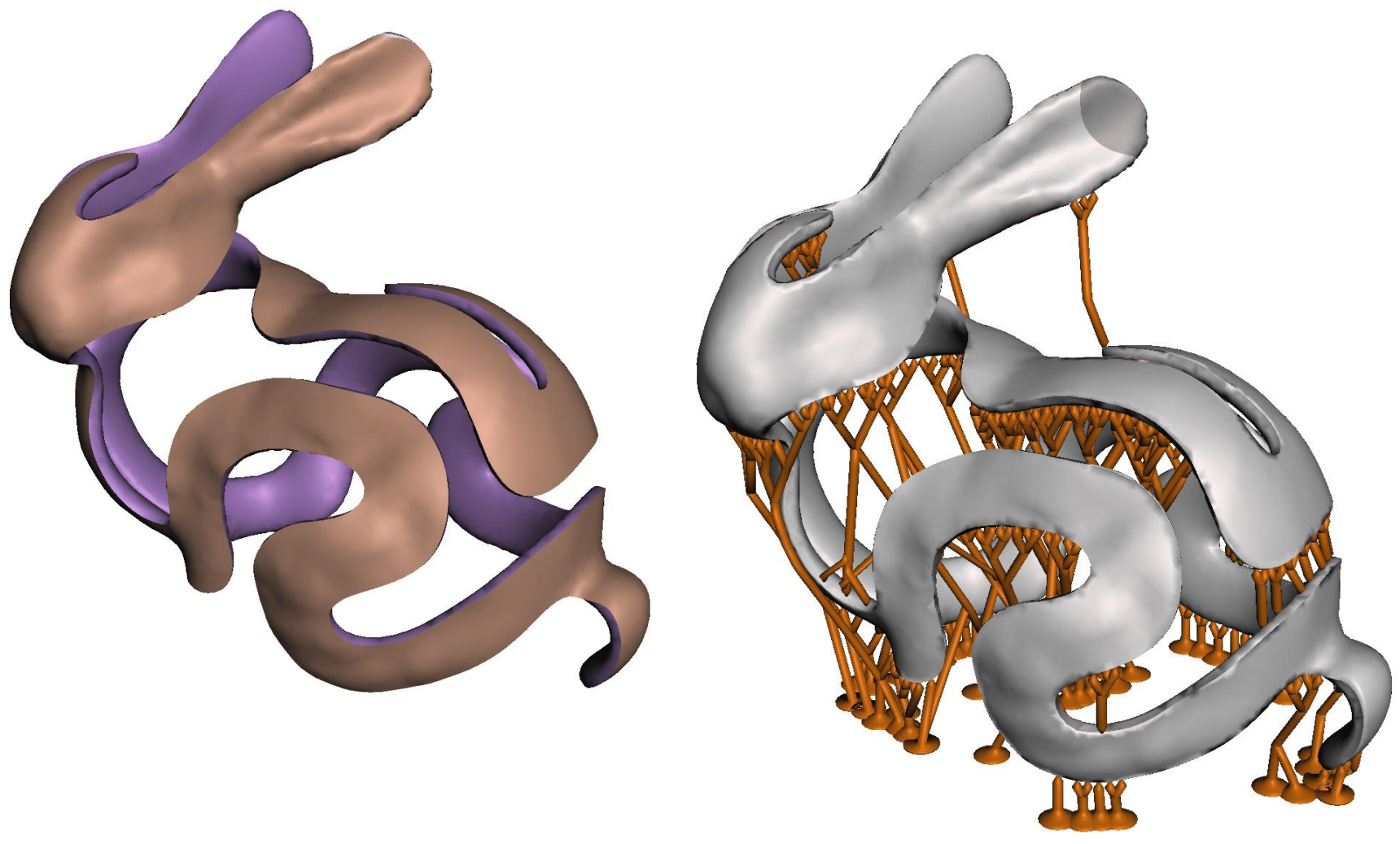

At the same time we released Meshmixer 2.0, I published my Bunny Peel model on Thingiverse, with pre-generated branching supports. With this example we used 1/4 the support material of standard supports, and cut print time by an hour. This was a Featured Thing for the week, and it got a lot of people trying our supports. Over the next few months there were many articles written about these support structures, and lots of great examples. At present, thousands of people generate Meshmixer supports structures every day, and many prints come out successful that would be really hard to do with traditional supports.

I have to give some credit to Dan Pressman for setting me on this direction. He had been creating single-post supports by hand, and suggested to me that we might be able to generate these posts automatically. I started with this basic concept, but using long angled posts to support individual points was much slower than the Makerbot support in most cases. So, I started clustering the posts, and eventually rewrote the entire algorithm to use a top-down grow-and-cluster strategy. Over time the method was improved with things like auto-generated reinforcement struts, graph pruning and postprocess-optimization, to maximize robustness during the print process.

In 2014 when the Autodesk Spark program and Ember printer was announced, the Ember team came to me and asked if we could adapt the branching supports - which were designed for FDM - for Ember's DLP-SLA printing technology. We found that this was not too difficult, and as a result when Ember shipped, Meshmixer was provided as a printing tool. Eventually this adaptation of the support generator was rewritten and improved by the Spark Print Studio team.

Although the methodology behind my support generator has not been formally published, I have given talks about the technique at SIGGRAPH 2014 and RAPID 2015. Our work on more complex support structures also inspired various academic publications, I particularly was impressed by Bridging the Gap by Dumas et al. Branching supports eventually showed up in other printing tools, but still today most of them either are much more manual intervention, or lack the ability to really "go around" the model, to minimize the number of top-connections.

The Ember Logo, printed on an Ember, with Meshmixer-generated support structures

The Spark Print Studio launch screenshot, with my support structures